20M-60M High Mast Light with Safety Cage Ladder

Main components of high mast lights:

Light pole: usually made of steel or aluminum alloy, with good corrosion resistance and wind resistance.

Lamp head: installed on the top of the pole, usually equipped with efficient light sources such as LED, metal halide lamp or high pressure sodium lamp.

Power system: provides power for lamps, which may include controller and dimming system.

Foundation: The bottom of the pole usually needs to be fixed on a solid foundation to ensure its stability.

Safety cage ladder: Attached to the exterior of a light pole, this steel ladder wraps around the pole in a spiral or straight pattern. It features guardrails to ensure safety during the climb and is typically wide enough for one person to ascend and descend with tools.

1. Height:

High mast lights usually have a taller pole, usually between 15 meters and 45 meters, and can cover a wider lighting area.

2. Light source type:

High mast lights can use a variety of light sources, such as LED, metal halide lamps, sodium lamps, etc., to adapt to different lighting needs. LED floodlight is a very popular choice.

3. Lighting range:

Due to its height, it can provide a larger lighting range, reduce the number of lamps, and reduce installation and maintenance costs.

4. Structural design:

The design of high mast lights usually takes into account factors such as wind force and earthquake resistance to ensure stability and safety under severe weather conditions.

5. Adjustability:

Some high mast light designs allow the angle of the lamp head to be adjusted to better meet the lighting needs of a specific area.

1. Improve safety:

High mast lights can provide uniform lighting, reduce shadows and dark areas, and improve the safety of pedestrians and vehicles.

2. Energy saving and environmental protection:

Modern high mast lights mostly use LED light sources, which have high energy efficiency and can significantly reduce energy consumption and maintenance costs.

3. Aesthetics:

The designs of high mast lights are diverse and can be coordinated with the surrounding environment to enhance the aesthetics of the urban landscape.

4. Durability:

High mast lights are usually made of corrosion-resistant materials and waterproof designs, which can be used for a long time in various climate conditions and have low maintenance costs.

5. Flexible installation:

High mast lights can be flexibly arranged as needed to adapt to the lighting needs of different places, and installation is relatively simple.

6. Reduce light pollution:

The design of modern high mast lights pays attention to the directionality of light, which can effectively reduce light pollution and protect the night sky environment.

| Height | From 20 m to 60 m |

| Shape | Round conical; Octagonal tapered; Straight square; Tubular stepped;Shafts are made of steel sheet that folded into required shape and welded longitudinally by automaticarc welding machine. |

| Material | Usually Q345B/A572,minimum yield strength>=345n/mm2. Q235B/A36,minimum yield strength>=235n/mm2. As well as Hot rolled coil from Q460, ASTM573 GR65, GR50, SS400, SS490, to ST52. |

| Power | 150 W- 2000 W |

| Light Extension | Up to 30 000 m² |

| Lifting system | Automatic Lifter fixed in the inner of the pole with lifting speed of 3~5 meter per minute. Euqiped e;ectromagnetism brake and break –proof device, manual opeation applied under power cut. |

| Electric appliance control device | Electric appliance box to be be the holde of the pole ,lifting operation could be 5 meter away from the pole through wire. Time control and light control could be equipped to realize full-load lighting mode and part lighitng mode. |

| Surface treatment | Hot dip galvanized Following ASTM A 123, color polyester power or any other standard by client required. |

| Design of pole | Against earthquake of 8 grade |

| Length of per section | Within 14m once forming without slip joint |

| Welding | We has past flaw testing.Internal and external double welding makes the welding beautiful in shape. Welding Standard: AWS ( American Welding Society ) D 1.1. |

| Thickness | 1 mm to 30 mm |

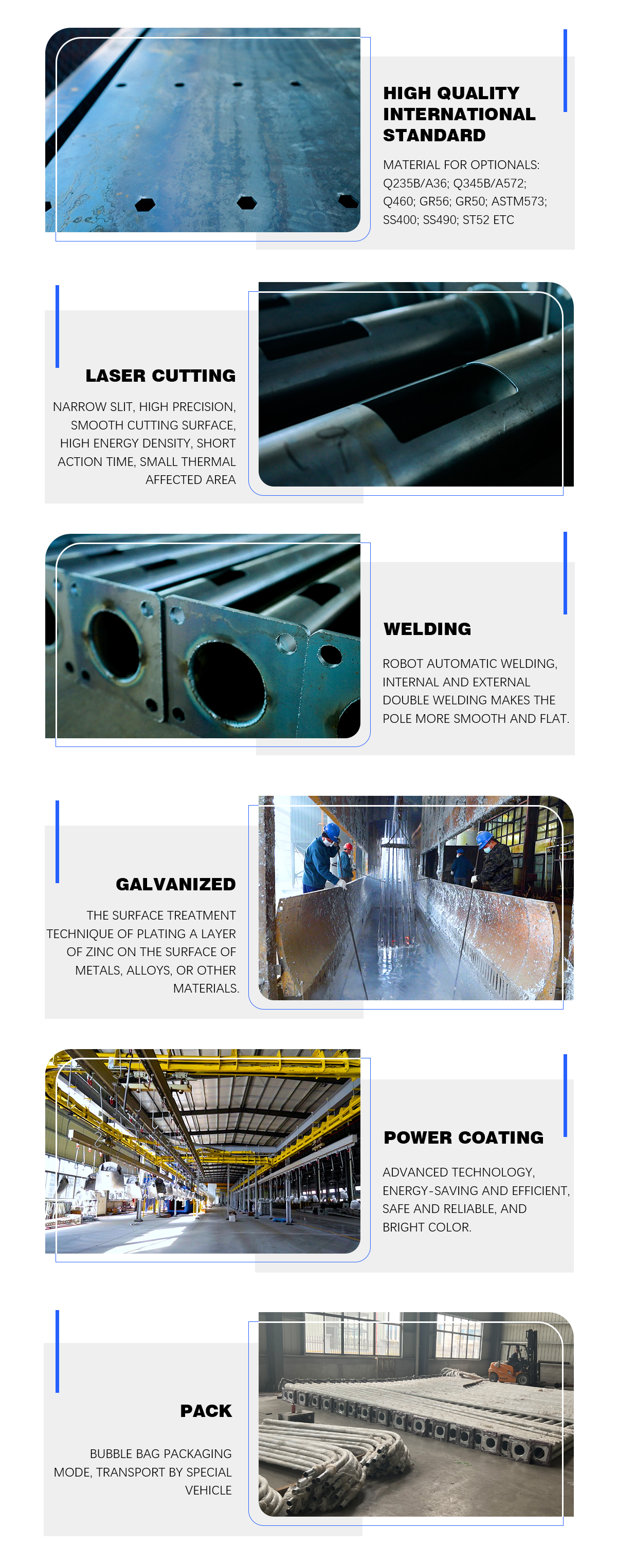

| Production Process | Rew material test → Cuttingj →Molding or bending →Welidng (longitudinal )→Dimension verify →Flange welding →Hole drilling →Calibration → Deburr→Galvanization or powder coating ,painting →Recalibration →Thread →Packages |

| Wind resistance | Customized, according to customer's environment |

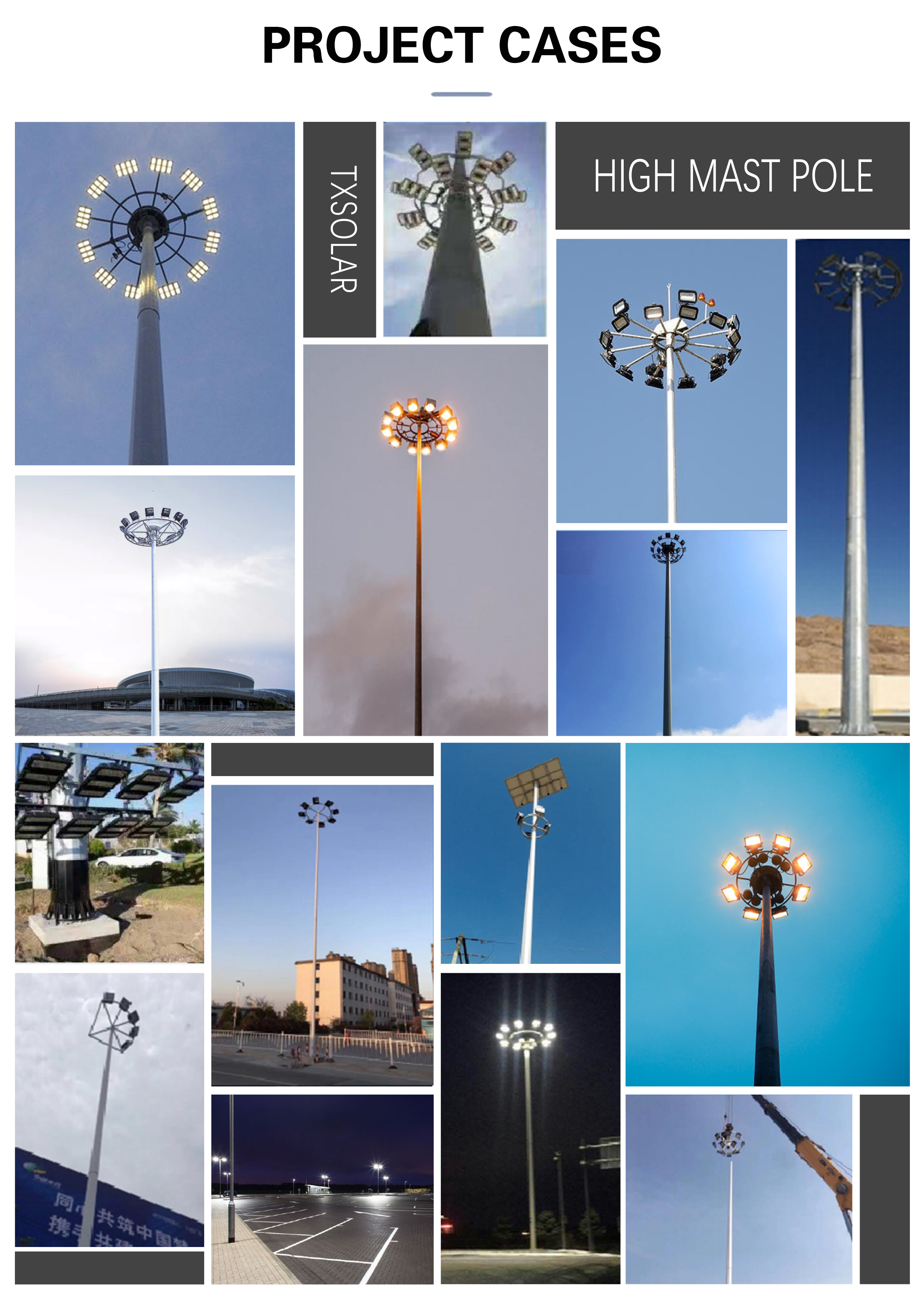

Road Lighting:

High mast lights are often used for lighting urban roads, highways, bridges and other traffic arteries to provide good visibility and ensure driving safety.

Square Lighting:

In public places such as city squares and parks, high mast lights can provide uniform lighting and improve the safety and comfort of night activities.

Sports Venues:

High mast lights are often used for lighting in stadiums, sports fields and other places to meet the lighting needs of competitions and training.

Industrial Area Lighting:

In large industrial areas, warehouses and other places, high mast lights can provide efficient lighting to ensure the safety of the working environment.

Landscape Lighting:

High mast lights can also be used for urban landscape lighting to enhance the beauty of the city at night and create a good atmosphere.

Parking Lot Lighting:

In large parking lots, high mast lights can provide extensive lighting coverage to ensure the safety of vehicles and pedestrians.

Airports and Terminals:

High mast lights also play an important role in lighting airport runways, aprons, terminals and other areas to ensure the safety of aviation and shipping.

1. Q: What is the illumination range of a high mast light? Does the illumination range vary between high-mast lights of different heights?

A: Generally speaking, a 15-meter-high high-mast light has a lighting radius of approximately 20-30 meters, a 25-meter-high one reaches 40-60 meters, and one 30 meters or higher covers 60-80 meters. We provide customized height and lighting combinations based on specific site requirements.

2. Q: What is the wind resistance rating of the high mast light? Can it be used in coastal areas prone to typhoons?

A: Our high mast lights have a wind resistance rating of up to Force 10 (wind speeds of approximately 25 meters per second). For coastal areas prone to typhoons, we can customize reinforced structures to increase the wind resistance to Force 12 (wind speeds of approximately 33 meters per second).

3. Q: What are the site conditions required for installing a high mast light? What are the foundation requirements?

A: The installation site must be flat and open, with no tall buildings blocking the light. Regarding the foundation, the diameter of a 15-20 meter high mast light is approximately 1.5-2 meters, and the depth is 1.8-2.5 meters. For high mast lights over 25 meters, the diameter is 2.5-3.5 meters, and the depth is 3-4 meters. Reinforced concrete is required. We will provide detailed foundation construction drawings.

4. Q: Can the power of the high mast light be customized? Can the brightness be adjusted according to actual needs?

A: The power can be customized. The power of a single lamp ranges from 150W to 2000W, and the total power can be adjusted based on the site area and lighting needs.